In my role as Application Scientist and Frontier pyrolyzer super-user for Quantum Analytics, I have talked to and worked with many pyrolysis users with varied experience levels. If you’re reading this article, there is a good chance you are already a user of the Frontier EGA/PY-3030D Multi-Shot Pyrolyzer or have done some research into Pyrolysis-GC-MS. On your path to building expertise on this technique, be sure to avoid these common misconceptions about pyrolysis. From liquid injections to pyrolysis itself, let us offer some clarity so you can use your system and resources to best fit your analytical needs.

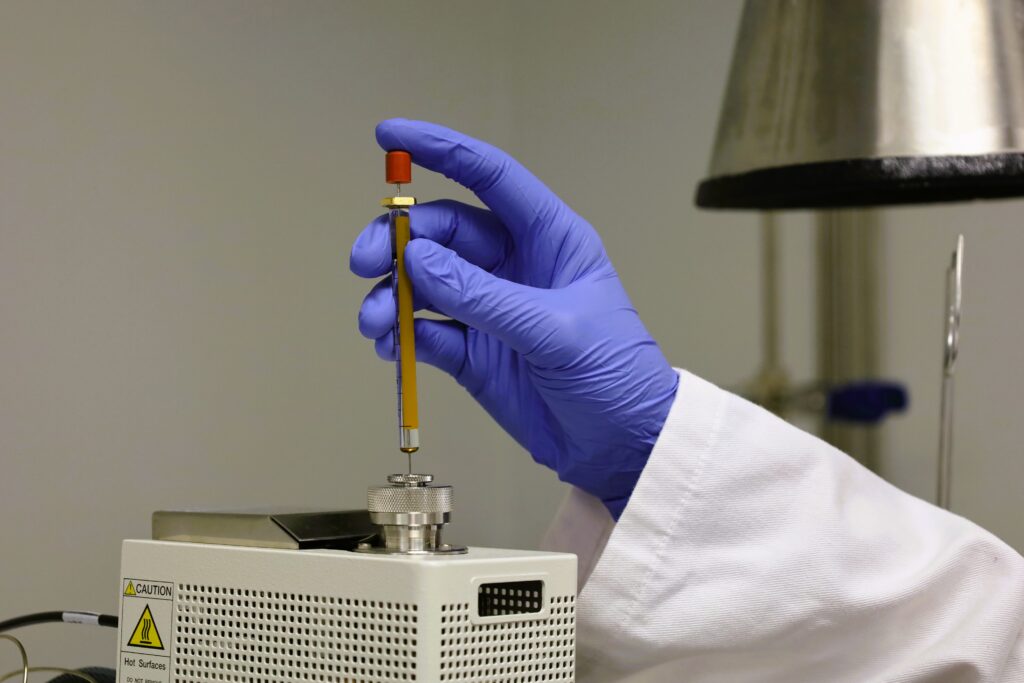

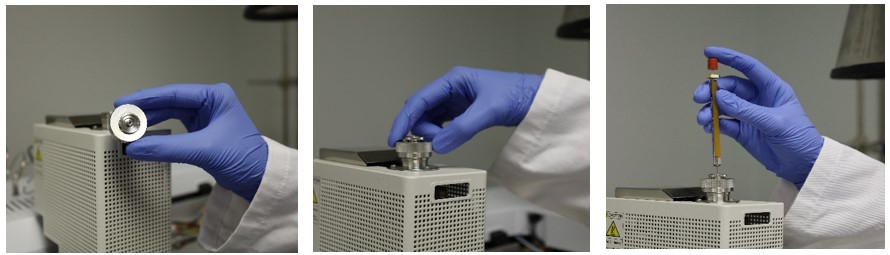

The most common misconception surrounds the topic of liquid injections. Many new users are under the impression that they are unable to perform liquid injections with the Pyrolyzer installed on the GC inlet. They assume the furnace must be completely disassembled to inject with a syringe, which is not the case. Included with each system is a simple yet powerful tool, the Liquid Sampler, which supports manual injections without removing the pyrolysis system itself.

To make a liquid injection, attach the Liquid Sampler, set the furnace temperature 50°C above the inlet temperature, and set up for manual injection.

![]()

For autosampler users, liquid can also be dispensed into the Eco-cups. Eco-cups have beveled bottoms, which allow for surface tension to hold liquid. Some users also like to top the Eco-cup with glass wool to prevent splash back when the Eco-cup free-falls into the furnace.

If you are worried about dedicating a GC to pyrolysis-only work, and not being able to add a tray and tower for traditionally automated liquid injections, have no fear! The Frontier pyrolyzer has a sideways-mount option, which allows one GC with two inlets to have a pyrolyzer (with autosampler!) on one, and a tower and tray on another. (For help related to configurations, reach out to Quantum Analytics. Quantum Analytics is the only company factory-trained and qualified to integrate the Frontier Lab solution with Agilent’s GC portfolio. We are channel partners of both Agilent Technologies and Frontier Lab, and our technical specialists can help you achieve your specific application needs.)

To accurately discuss data, it’s crucial to understand the concept of pyrolysis itself. Pyrolysis is the thermal decomposition of a polymer or compound. But it is easy to overlook that this occurs in the absence of oxygen. Some users have likened the process that occurs in the micro-furnace to melting, boiling, combustion, atmospheric decomposition, and mass loss. However, these processes often take place in air.

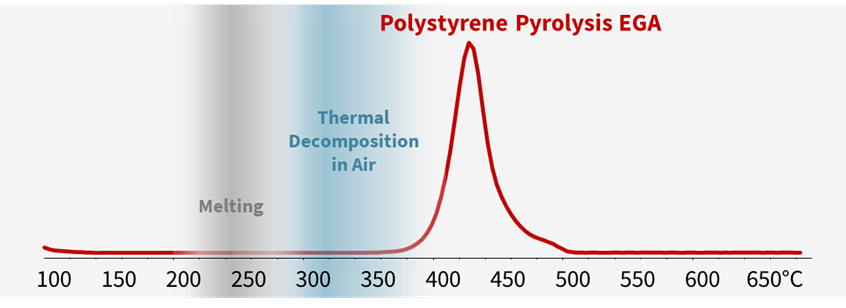

As an example, we look at an evolved gas analysis (EGA) thermogram of a polystyrene sample. The EGA is obtained by raising the furnace temperature at a constant rate while feeding all pyrolyzates from the sample directly to a mass spectrometer (no separation is involved here). The resulting curve is a response of temperature with a peak apex around 420 °C. This thermal profile is not to be equated to melting, combustion, or mass loss, as it is not the same (though there may be overlap). The EGA represents the temperatures at which the compound thermally degrades in the absence of oxygen. If the sample were exposed to oxygen or air, the reaction would be described as thermal decomposition in air rather than pyrolysis. For some analyses and compounds, combustion is an appropriate descriptor as well.

Interesting to note, that the air decomposition temperatures of polystyrene were obtained by the same system, but by introducing air into the micro-furnace using a carrier gas selector. (For users interested in studying like reactions, inquire with Quantum Analytics, as we can assist with carrier gas selectors [CGS-1050E] for your system.)

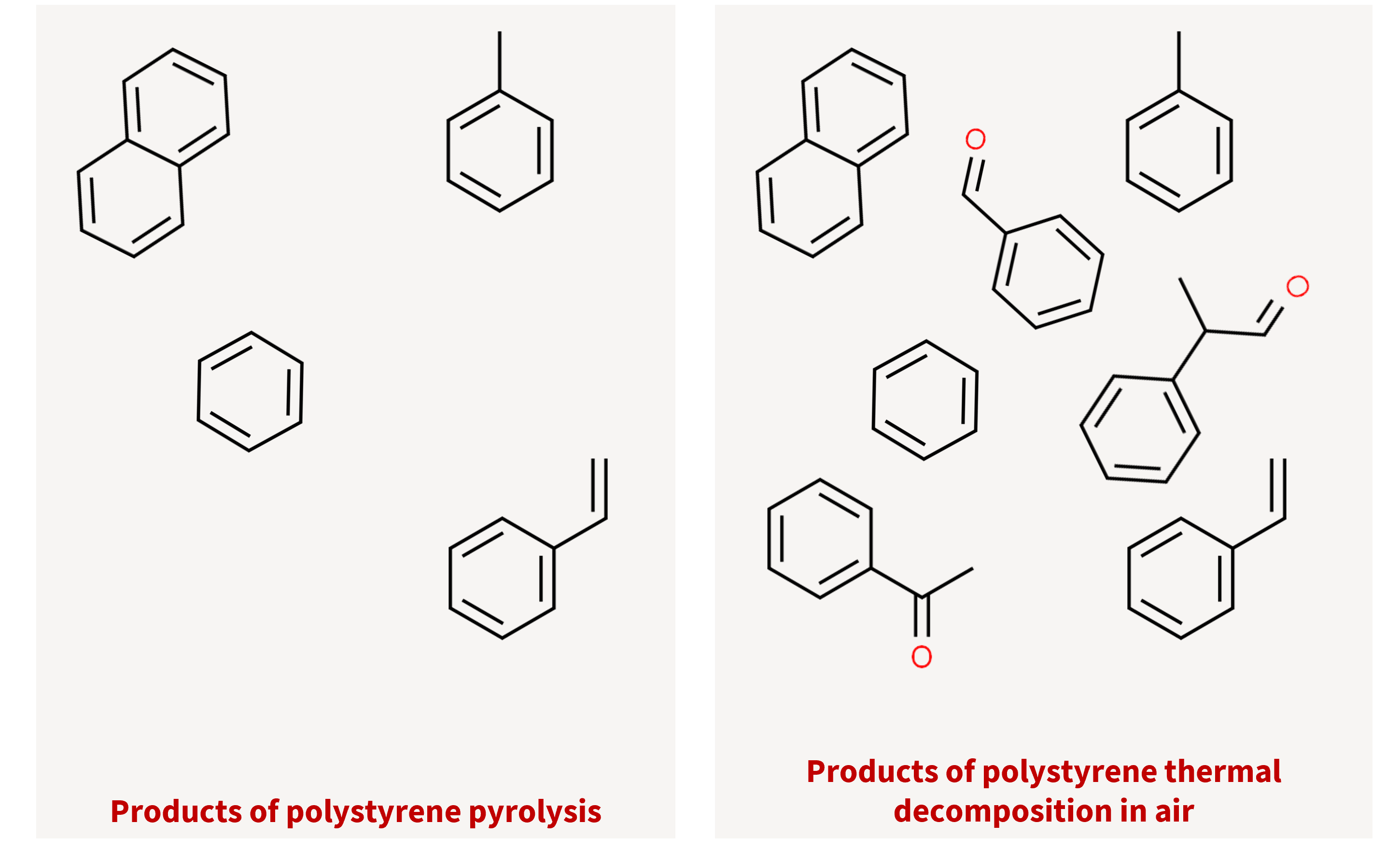

How would the byproducts of a thermally-degraded sample differ in air versus in inert gas? The products of pyrolysis are only influenced by thermal breakdown. With a carrier gas selector exposing the sample to air, you would see additional oxygenated compounds in your chromatography.

The Frontier system (and mass spectrometry in general) are used universally for qualitative analysis. Understandably, some users are reading between the lines to figure out the best way to approach quantitative analysis. We often see this myth overlap with another common misconception about pyrolysis: not being able to run liquid injections, as many calibration curves are made and run as liquids.

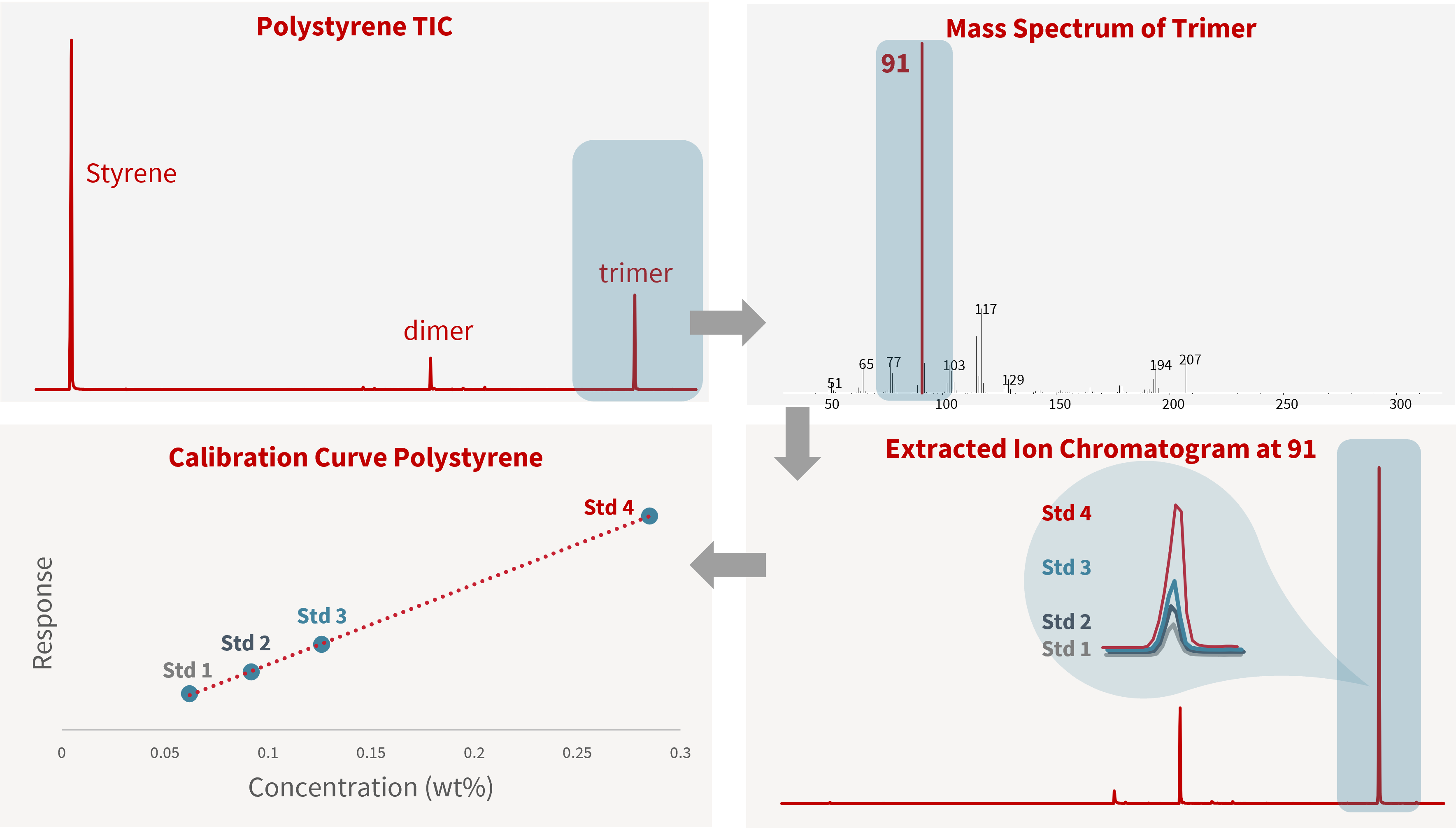

For quantification using the micro-furnace, it is recommended to discover an ideal thermal desorption or pyrolysis temperature for your analyte of interest using the various modes of operation. For quantification using mass spectrometry, it is recommended to pick a peak in your chromatogram that is unique and abundant, then to use an extracted ion from said peak that is again, unique and abundant. As an example, we show a calibration curve of polystyrene made by dissolving polystyrene in an appropriate solvent and making serial dilutions. All liquid calibrants were dispensed in Eco-cups at 10 µL each and run on the autosampler at a pyrolysis temperature of 550°C.

The last misconception is fortunately one that is easily addressed. For new and experienced users, it may seem like a lot to keep up with the various libraries, modes of operation, and accessory units on top of learning mass spectrometry and chromatography. Fortunately, the Frontier system and respective software solutions are designed to be intuitive and simple to use. Plus, there are ample application notes to guide self-learning and method development. Of course, there is always support and training options for users of all levels. Quantum Analytics’ Skill-Up Training Program includes a training program for Pyrolysis-GC/MS. This training program can be tailored to users who are completely new to this technique, or existing users who want a comprehensive training to fill gaps in their learning. Entry-level trainees can learn in a step-by-step approach and cover the basics before moving to advanced topics. Experienced users can build on their experience by going more in-depth on the analysis and using F-Search.

In summary, don’t let misconceptions about pyrolysis threaten your ability to operate a powerhouse solution that delivers game-changing results. Even if you are a seasoned user of an instrument, there might be a new development or feature that makes what seemed impossible with older models – become an awesome reality. If in doubt, discuss your application, analytical needs and experience-level with a team who understand the product in-and-out. Our Quantum Analytics technical team knows and understands the ideal scenarios (and the limitations) of the analytical instrumentation we support. We look forward to helping you discover if the Frontier solution can take your chromatography to new levels.

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions