When analyzing solids, liquids, and gases, many labs turn to gas chromatography mass spectrometry (commonly referred to as GC-MS). But often, labs need their characterization capabilities to go further. For example, when analyzing polymers and other materials, or the sample is insoluble in any solvent.

In this post, we’ll explore why labs turn to Pyrolysis GC/MS systems to enhance their analytical testing, and why the Frontier pyrolyzer is the industry-preferred solution.

Why Pyrolysis-GC/MS?

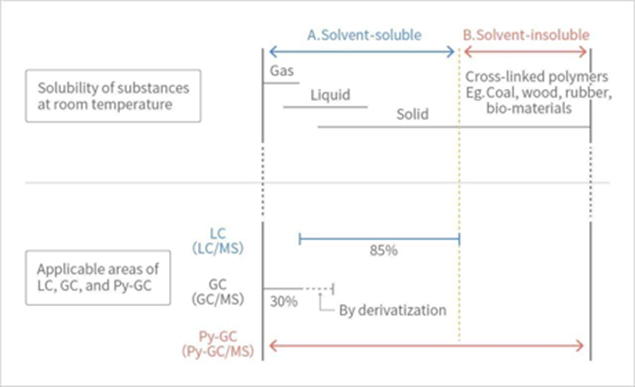

When analyzing liquids and gases using a GC/MS system, the sample is commonly directly injected into the GC. But when it comes to solids, GC/MS analysis requires some assistance by way of solvent extraction, outgassing (desorption), or pyrolysis. Frontier Micro-Furnace Pyrolysis GC/MS expands the range of organic composition analysis from gases to solids, even those that are insoluble in any solvent.

Image 1 (below) shows how analytical pyrolysis can be applied to wider areas of analytical targets than other analytical techniques, including solvent-soluble (gas, liquid and solid) and solvent-insoluble samples (coal, wood, rubber, biomaterials, and other cross-linked polymers).

Image courtesy of Frontier Laboratories Ltd.

Image courtesy of Frontier Laboratories Ltd.

How does Micro-Furnace Pyrolysis-GC/MS work?

Let’s take a step back and explore how micro-furnace Pyrolysis GC/MS works. Sample introduction is nearly instantaneous. The sample is placed in an inert sample cup and is held at near ambient temperature in helium. The micro-furnace is then preheated to the desired temperature that is precisely measured with a thermal couple sensor. The sample cup then drops into the quartz pyrolysis tube where the sample is pyrolyzed in milliseconds. The pyrolyzates are then directly and continuously swept onto the GC analytical column for separation and detection by MS.

The sample is broken down into smaller stable components called “pyrolyzates” for analysis. The pyrolyzates are then chromatographically separated, like traditional GC/MS. Once the pyrolyzates are separated, the data is interpreted to gain insight into the original material.

It is important to know that Pyrolysis GC/MS is a destructive technique, and it is mostly applicable to organic samples.

Why labs turn to pyrolysis for sample preparation

As we outlined earlier, pyrolysis extends the capabilities of standard GC/MS systems. For labs that already have a GC-MS system in operation, and the staff to operate it, pyrolysis is a manageable way to enhance an already powerful instrument.

With a Pyrolysis GC/MS system, this enhanced capability opens an exciting terrain of application possibilities:

What are the different types of pyrolyzers?

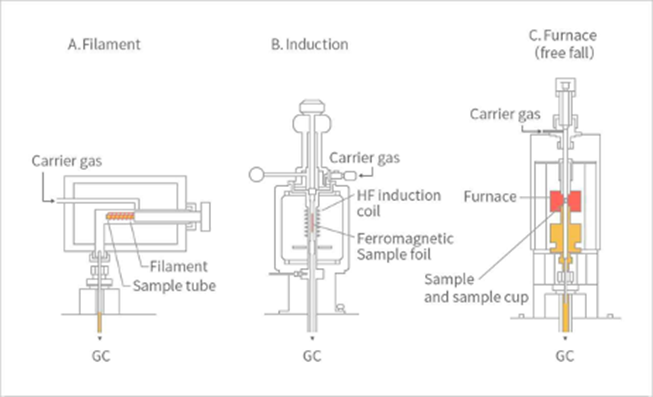

Not all pyrolyzers are created equal. Commercially-available pyrolyzers can be categorized into three groups:

Filament type pyrolyzer heats a sample tube with a filament

Induction type pyrolyzer heats a sample foil by high-frequency magnetic field

Furnace type pyrolyzer heats a sample by dropping a sample cup into a heated furnace

Image courtesy of Frontier Laboratories Ltd.

The filament-type pyrolyzer has a drawback in temperature accuracy. This means that a sample being analyzed may not be uniformly heated, which can lead to poor reproducibility. Plus, high boiling compounds may be absorbed in the transfer line that sends the pyrolyzates to GC. This makes it difficult to introduce high boiling compounds to a GC column.

The induction-type pyrolyzer should theoretically have a high furnace temperature accuracy. However, a sample cannot be ramp-heated as required for EGA-MS analysis. Further, the way the sample is wrapped with a metal alloy foil can vary and this leads to poor reproducibility.

The furnace-type pyrolyzer requires a sample to be placed in an inert sample cup, which is then dropped (free fall) into a preheated furnace. When performing Pyrolysis-GC/MS with a furnace-type pyrolyzer, there are advantages over filament-type and induction-type pyrolyzers:

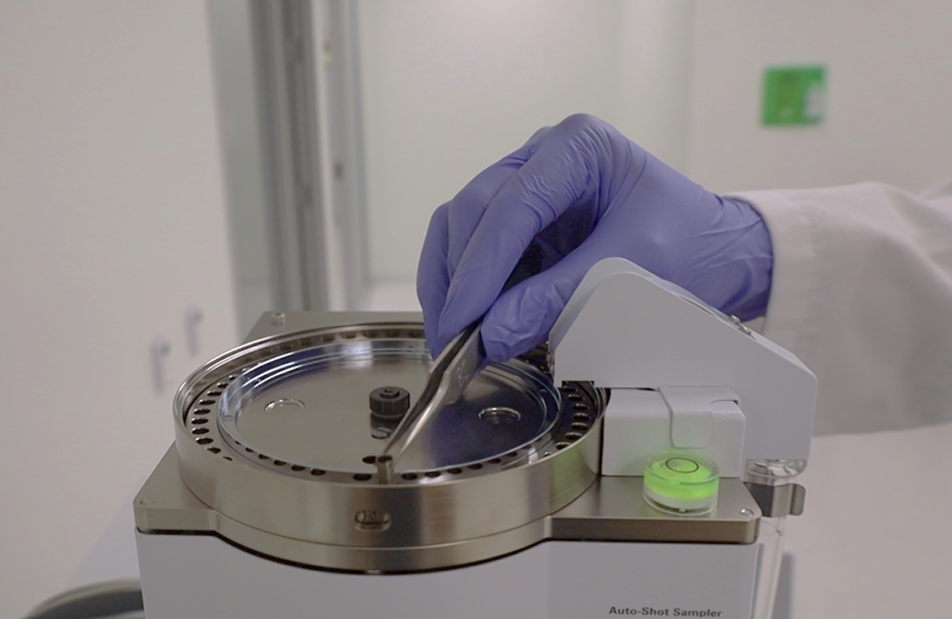

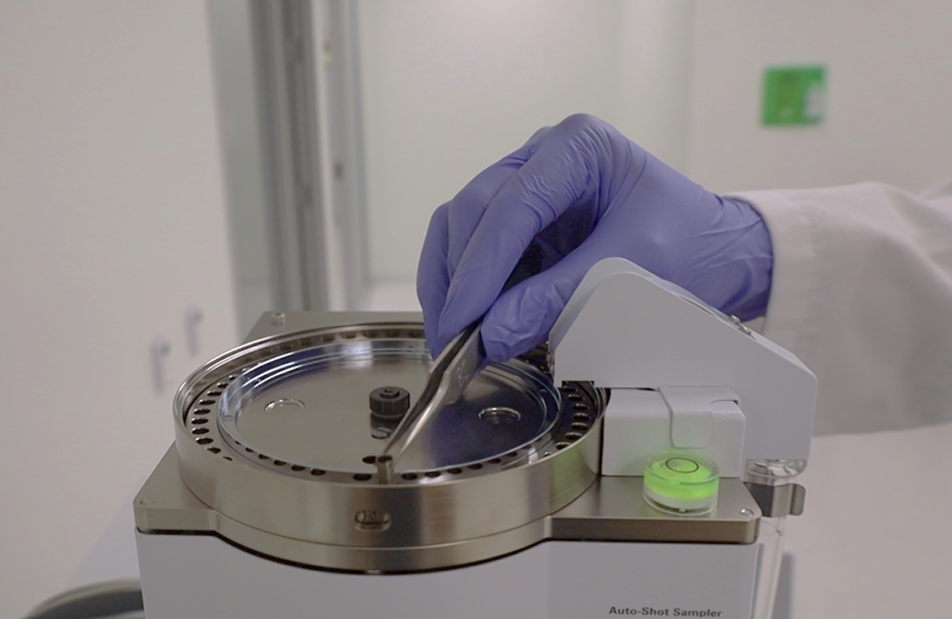

Placing a Frontier Eco-Cup sample cup into the Frontier Auto Shot autosampler.

The Frontier EGA/PY-3030D is a versatile multi-shot pyrolyzer that is based on the furnace-type pyrolyzer design. It offers temperature programmability from ambient (+10ᵒC) to 1050ᵒC with precise temperature control (+/- 0.1ᵒC) of the ceramic micro furnace. This allows the user to analyze materials using a variety of techniques for greater flexibility.

Why Quantum Analytics

For nearly two decades Quantum Analytics has been an authorized distributor of the Frontier pyrolysis portfolio. Our long partnership has solidified our position as the go-to resource for application expertise around extending the capabilities of Agilent GC/MS using Frontier pyrolysis solution. Our extensive technical knowledge ensures that our clients gain value from their investment in a Frontier instrument for years to come.

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions