Article

Uncover the hidden benefits of rental-with-equity programs and learn how to turn your lab’s dreams into reality.

As greenhouse gas (GHG) monitoring becomes more crucial for a sustainable future, there is a need in the industry for improved greenhouse gas analyzers. Environmental samples must be analyzed within appropriate holding times. Neglecting to promptly run a sample can lead to erroneous results. For example with vials, the sample concentration can be incorrect by up to 22% v/v with delayed testing, while samples tested within 28 days of collection are not impacted.¹

There are a variety of allowable hold times depending on the analyte and method. (Here is a link to a helpful reference guide from Eurofins that shows holding times and containers for water/aqueous samples). It is crucial that laboratories do not fall behind in testing to maintain accurate results. A major contributor to downtime in laboratories is equipment failure. We will explore an innovation in the chromatography industry to improve greenhouse gas analyzers.

The majority of greenhouse gas analyzers leverage reduction catalyst to quantify carbon dioxide with an FID at trace levels (<50 ppm). A methanizer/FID is capable of CO2 detection down to 20 ppb. A simple design for an analyzer is to use two channels with an electron capture detector (ECD) for N2O and a methanizer/FID for CO2 and methane quantification. Analyzers have classically used a third channel with a TCD to handle larger concentrations of CO2. The main reason is that legacy methanizers have been unable to reproducibly reduce larger volumes of CO2 to methane. This additional channel comes with added complexity and cost of an extra detector, valve, and columns. With each addition to the system, we are exposed to one more potential source for a leak and failure. A simpler design increases robustness by reducing points of failure.

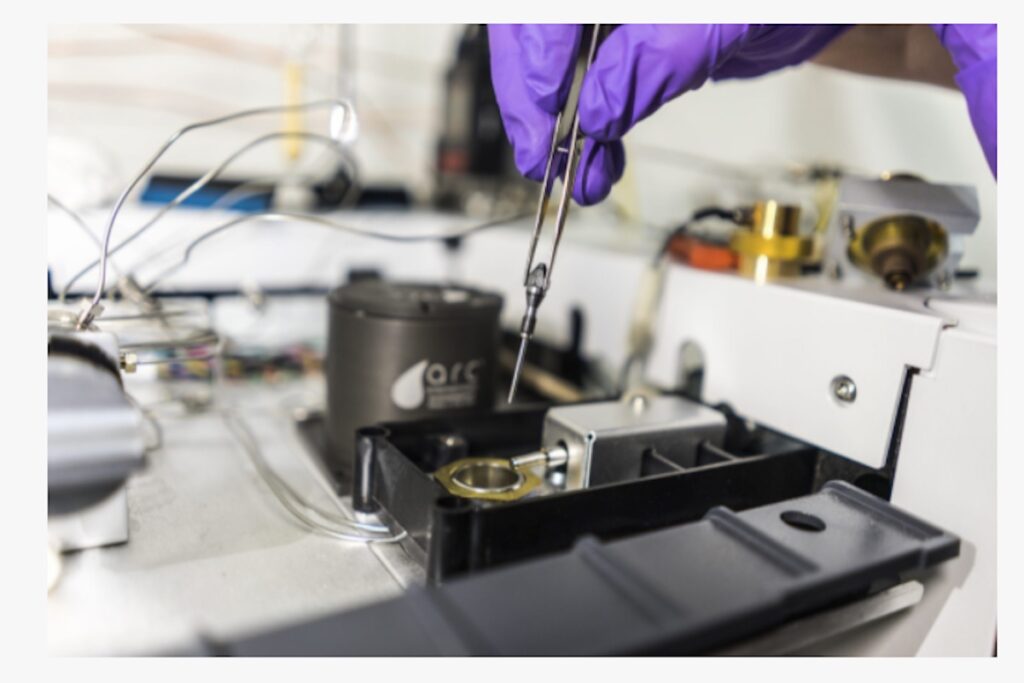

Image 1: Jetanizer, manufactured by Activated Research Company, is a robust, easy-to-use methanizer that offers drastically simple analysis of CO and CO2. It is available in multiple sizes, depending on the GC make and model and FID type it is being installed with.

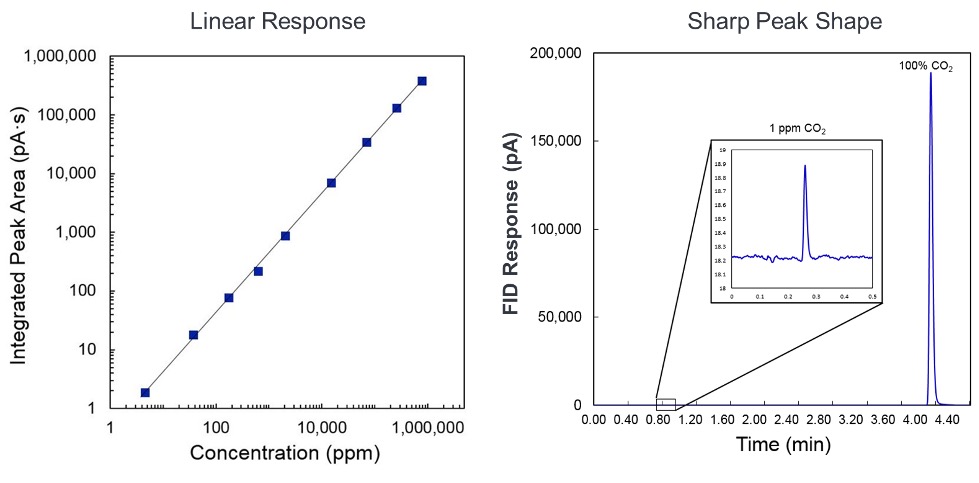

An improved methanizer technology is the Jetanizer from Activated Research Company. It has non-nickel catalyst that can convert pure CO2 to methane. This allows for analysis of the full range of CO2 without necessitating a TCD to cover quantify the higher range. Along with the simplified design of the greenhouse gas analyzer, a Jetanizer can be replaced in less than 5 minutes.² Linear response and peak shape are demonstrated below in Figure 1.

Figure 1 | Jetanizer Performance. The graph on the left demonstrates the linear response for CO2 with the Jetanizer across six orders of magnitude. On the right is the expected peak shape and noise when using the Jetanizer.

Old legacy methanizers require significant personnel time (sometimes over 2 hours) to change the catalyst. Replacement of catalyst requires deconstructing the methanizer weldment body. Since the fittings have been exposed to thermal cycling in the oven, the fittings are ripe for seizing and damage. The laboratory staff must handle and dispose of the toxic spent nickel catalyst. New nickel is packed into the reactor tubes, which is a safety concern and should not be a rushed tasked. With the reactor rebuilt, it is installed with hopefully functional fittings.

The alternative is to spend 5 minutes swapping out a standard FID jet with a Jetanizer. The Jetanizer conditioning time is relatively short, taking only about 40 minutes to remove any accumulated carbon. [Next time a methanizer fails at 4pm before the weekend run, a five-minute replacement would be preferred!]

Image 2 shows how the Jetanizer is installed in the FID like a normal jet. After removing the FID jet, the Jetanizer takes its place. Installation time is typically less than 5 minutes.

The other major benefit of the Jetanizer’s robust catalyst is that it can tolerate more exposure of oxygen, sulfur, and alkynes without failure³. All these benefits lead not only to a more durable reactor design, but also better GHG analyzers that will have less frequent downtime. When there is downtime, it can be minimized by quick replacements.

It does need to be acknowledged that having a TCD on the third channel of a greenhouse gas analyzer provides benefits with the premium cost; run times can be shorter and there is more flexibility because there is less pressure on valve switching. Regardless of what technique you use for greenhouse gas analysis, our future generations will be thankful that you are doing it.

Learn more on this topic by watching on-demand webinar, Simplified Environmental Testing with GC-FID, featuring guest presenter, Connor Beach.

Ready to try out the Jetanizer in your lab? Purchase yours today from our Online Store!

References:

[1] Faust, D. R., & Liebig, M. A. Effects of storage time and temperature on greenhouse gas samples in exetainer vials with chlorobutyl SEPTA Caps. MethodsX, 5, 857–864. (2018). https://doi.org/10.1016/j.mex.2018.06.016

[2] Methanizer (Jetanizer™). Activated Research Company. (2022, May 18). Retrieved July 6, 2022 from https://www.activatedresearch.com/jetanizer-methanizer-astm-d6158-astm-d2505-uop603-18/

[3] Impacts of Hydrogen Sulfide and Acetylene on ARC In-jet Methanizer Performance. Shimadzu Application News. No. SSI-GC-2108. Retrieved March 9, 2022.

Put our expertise, strategic partnerships, and technical support capabilities to work for you.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

© 2024 Quantum Analytics | A Black Forest Ventures Company | All Rights Reserved | Privacy Policy

Complete this form below to sign up and we will reach out to you with instructions