Article

Uncover the hidden benefits of rental-with-equity programs and learn how to turn your lab’s dreams into reality.

Reverse engineering describes the process of dissembling a particular material and analyzing it. This process is also referred to as deformulation. The reverse engineering process, although challenging, can provide valuable insights into the true makeup of a particular material for the reformulation or product improvement process.

Many companies do this to gain a deeper understanding of the physical properties of a particular material. Especially when the material is related to a competitive product.

There are many tools that can help an analytical chemist with their reverse engineering processes. Some examples include gas chromatography, pyrolysis, thermal desorption, atomic spectroscopy, and molecular spectroscopy. In this article, we’ll focus on the use of infrared spectroscopy, specifically FTIR imaging, in reverse engineering of materials.

Infrared spectroscopy is among the most powerful tools in the reserve engineering process. Each molecule has a unique infrared signature supplying great specificity in the identification process.

FTIR is a classic reverse engineering technique that can be used to determine a polymer class and family. Although it is generally a surface technique, it can determine whether a material has been contaminated and in some cases, degraded.

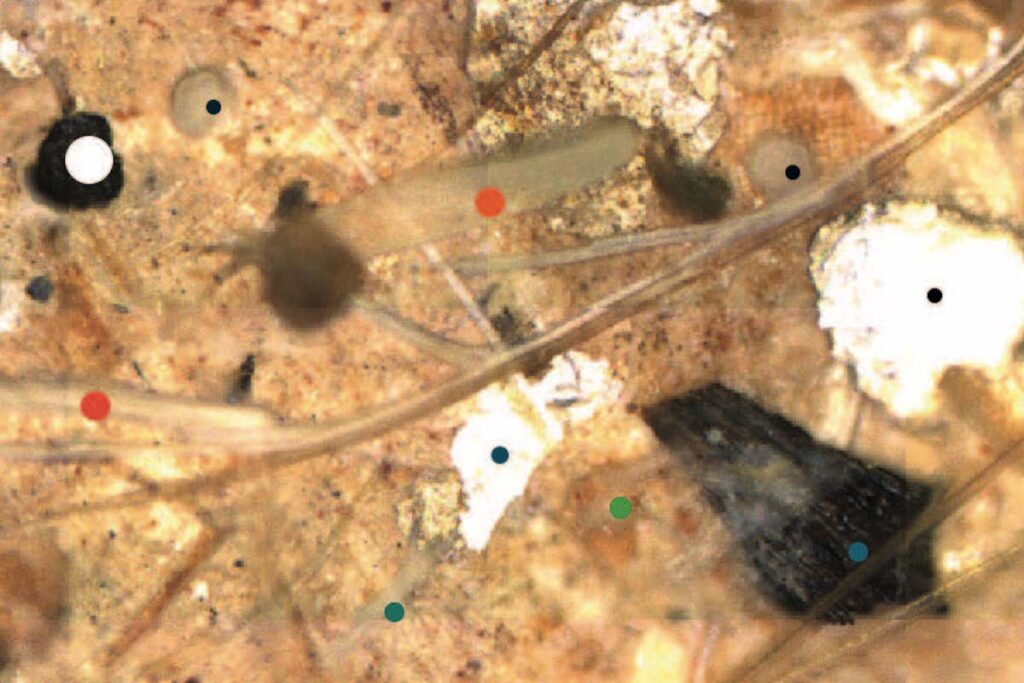

The Bruker LUMOS II is a stand-alone FTIR (Fourier Transform Infrared) imaging microscope. It provides ultrafast FTIR imaging capabilities using focal-plane array (FPA) detectors in its high-end version. It is designed to identify particles, determine coatings and contaminations, and reveal polymeric compositions.

A growing number of labs turn to the LUMOS II FTIR imaging microscope for quality control and failure analysis in various industries, such as pharma, polymers, chemical and electronics, as well as in forensics applications.

FTIR is one of the most important analytical techniques in polymer science. It enables scientists to track the causes of product defects, such as inclusions impurities and inhomogeneities. The LUMOS II can help uncover the chemical composition of complex materials, multilayer structures, laminates, composite materials and varnishes.

Learn more about the LUMOS II FTIR Imaging Microscope and its use in materials analysis and reverse engineering. Register for the webinar, “Reverse Engineering & Quality Control via FTIR”.

Put our expertise, strategic partnerships, and technical support capabilities to work for you.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

© 2024 Quantum Analytics | A Black Forest Ventures Company | All Rights Reserved | Privacy Policy

Complete this form below to sign up and we will reach out to you with instructions