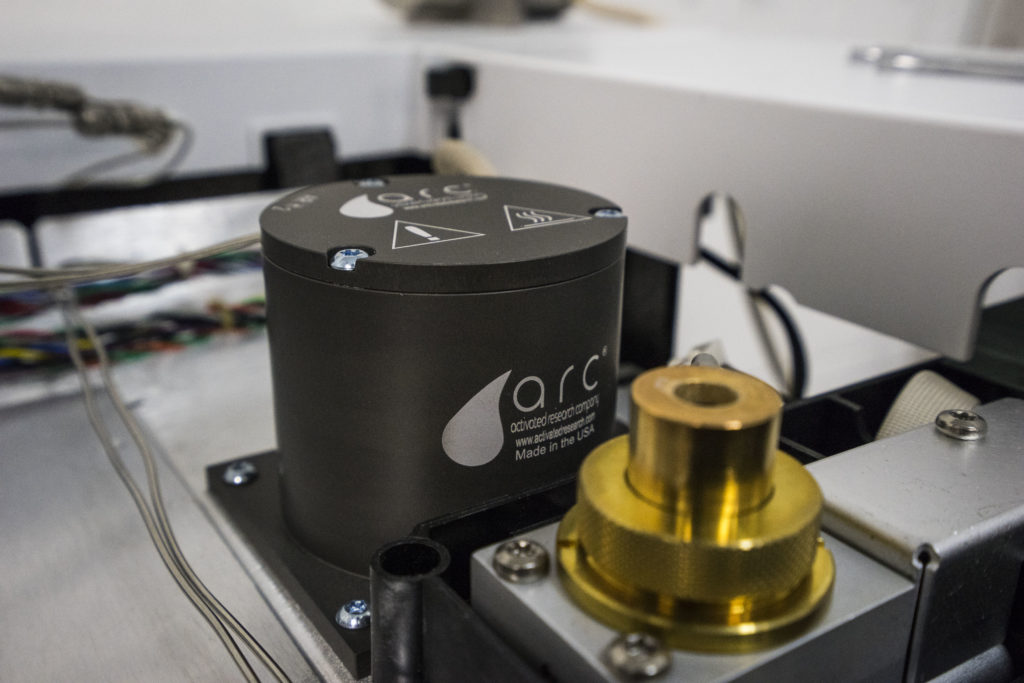

The Polyarc system is an add-on device for GC/FID analysis that completely converts all organic compounds to methane via a two-step combustion-reduction reaction for a uniform carbon response in the FID. This allows for more accurate quantification, increased sensitivity for certain compounds, compound independent calibration, and overall simpler analysis.

The integration of the Polyarc System into laboratory workflows unlocks numerous benefits that significantly enhance analytical results:

Read more about the benefits of the Polyarc in this latest article.

Yes. The Polyarc is a post-column, pre-detector add-on device, so an FID is necessary for detection of your analytes. Another common configuration for the Polyarc incorporates a post-column splitter with tandem MS and Polyarc/FID detection, resulting in single injection identification and quantification.

The Polyarc can be installed in any open position that has an access point to the GC oven. For Agilent instruments, this means: front/back detector, front/back inlet, valve box position (if no valve box is installed), and auxiliary detector position (where the MS is typically installed). It can be installed in detector positions of other GCs as well, including Shimadzu, Thermo Fisher, PerkinElmer, Bruker, and more. There are different enclosure sizes recommended based on where the Polyarc is installed to ensure proper fit.

No additional software is required for using the Polyarc system, and it seamlessly integrates into your GC/FID instrument. Customers continue using their existing GC software (or manual controls on the GC) to integrate peaks, control the reactor temperature, and in some cases, the reactor flow rates of air and H2.

The Polyarc has been validated for use with helium, hydrogen, argon, and nitrogen as carrier gases, so minimal changes to your existing methods are made. Please note that when using hydrogen as a carrier gas, there are different operating parameters to ensure that the two-step reaction goes to completion.

The Polyarc and traditional methanizers both ultimately convert CO and CO2 into methane. However, the Polyarc has several significant advantages over traditional methanizers:

The Polyarc requires flows of air and hydrogen for the two-step reaction, and there is a minimal increase in the amount of gases consumed when compared to your existing methods. There are three options for controlling flow rates: ARC’s Electronic Flow Control module (recommended), ARC’s Manual Flow Control module, and, if using Agilent GCs, two channels of the Auxiliary EPC channel with the appropriate frits.

When using helium, argon, or nitrogen as a carrier gas, 2.5 sccm of air (zero air quality, less than 1 ppm CO2 and hydrocarbons) and 35 sccm of hydrogen are provided to the Polyarc. Additionally, we recommend reducing the FID hydrogen flow rate to 1.5 sccm, as this will be made up by the flow of hydrogen from the Polyarc. Please contact us for flow rates and other specifications when using hydrogen as a carrier gas.

There are a few options for controlling the temperature for the Polyarc system. For non-Agilent GCs and Agilent instruments prior to the 7890 model, ARC has an external temperature controller which must be used. For Agilent 7890 GCs and later models, an auxiliary heated zone (A1 or A2) or inlet/detector heated zone can be used if available; otherwise, ARC’s external temperature controller can be used in these cases as well.

The Polyarc system has been carefully engineered and optimized to convert any carbon-containing compound to methane with a conversion rate greater than 99.9%. It has been demonstrated to work on a wide range of compounds with varying size and functionality including, but not limited to, hydrocarbons, aromatics, oxygenates, derivatives, and compounds containing heteroatoms such as O, N, S, Cl, Fl, and Si, etc.

The only compound that is known to poison the catalyst is sulfur. High amounts of sulfur (>1,000 ppm by mass per injection) can reduce the lifetime of the catalyst, but there is a regeneration process that users can attempt which does decrease the overall sulfur capacity of the reactor.

The Polyarc internal geometries and design have been optimized to minimize peak broadening; that being said, 5-10% peak broadening can be seen. Peak tailing can also be observed and is accentuated by some heteroatoms, overloading the reactor (e.g., large solvent peaks), column bleed, and oxidation of inert coating on Polyarc transfer lines. An enhanced version of the Polyarc, the Polyarc Ultra, has been developed to improve (decrease) solvent tailing with certain solvents and improve peak shapes of active compounds.

The Polyarc benefits from being paired with the FID and is able to take advantage of the FID’s large linear dynamic range of seven orders of magnitude.

There are two compounds that the Polyarc can’t convert to methane, and these are tetrafluoromethane (CF4) and hexafluoroethane (C2F6). The carbon-fluorine bonds in these molecules are too thermodynamically stable, so they don’t allow the first step of the reactions (combustion) to go to completion.

The current version of the Polyarc is not recommended for use with cryogenic oven temperatures. There is a small amount of water produced in the two-step reaction, and when using cryogenic oven temperatures, this water will freeze in the outlet transfer line of the Polyarc.

The current version of the Polyarc has been optimized for use with capillary columns ranging from 0.25 mm to 0.53 mm in inner diameter. If the current version of the Polyarc is used with GCxGC applications, more band broadening will be observed. ARC is developing another version of the Polyarc which will be able to be used in GCxGC with flow and thermal modulation.

The Polyarc/FID can be used along with the MSD for simultaneous identification and quantification. In this configuration, an Agilent CFT splitter is installed at the exit of the column, splitting flows to both the Polyarc/FID and the MSD. This configuration has been successfully implemented in many industries, including paints & coatings, biofuels, flavor & fragrance, and more.

The Polyarc can increase the FID response for compounds which traditionally have low FID response. These compounds typically contain heteroatoms like O, N, Cl, F, etc. Examples of compounds where the response is drastically improved include CO, CO2, formic acid, formaldehyde, formamide, etc.

Use of the Polyarc does not necessitate individual calibration standards for quantification and because of this, any inlet discrimination or adsorption that is inherent to the GC will be evident once the Polyarc is installed. It is important to ensure that the GC/FID is operational with good chromatography prior to installing the Polyarc. Preventative maintenance, such as changing the inlet liner, changing the gold seal, cleaning the FID jet, is recommended prior to installing the Polyarc.

The Polyarc system requires minimal, if any, routine maintenance. The reactor is designed to operate without catalyst deactivation for an extended period of time. The only maintenance over time is replacing the reactor when needed, and there is an easy replacement cartridge model for this process.

There is a process by which customers can attempt to regenerate the catalyst, however, this regeneration process will decrease the overall capacity of the reactor.

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions