Low level detection of CO and CO2 is important in catalysis, hydrogen (H2) purity analysis, dissolved gas analysis (DGA) and transformer oil gas analysis (TOGA), ethylene/propylene monomers, safe entry analysis, and more. Traditionally, large nickel-catalyst-filled tube methanizers are used, however, they are prone to frequent failures, and they are difficult and time consuming to operate and maintain. ARC’s Jetanizer solves these challenges by improving response, robustness and ease of installation, by incorporating state-of-the-art catalysts into an FID jet. Moreover, the Jetanizer enables low level <1 ppm formaldehyde analysis by GC avoiding the pitfalls of HPLC analysis of formaldehyde.

Available on Agilent 7890, Agilent 8890, Agilent Intuvo 9000, as well as legacy models (5890, 6890).

How does the installation time compare with traditional methanizers?

Legacy nickel catalyst methanizers can take 2 to 6 hours to install and replace. Jetanizers take less than 5 minutes.

What benefits does Jetanizer offer over traditional methanizers?

- Lower up-front cost

- No extra plumbing: minimize fittings and leaks

- No extra heater or controller: utilizes heat from FID

- FAST installation: in as little as 60 seconds or less

- Higher sulfur tolerance

- Higher catalytic activity = larger linear dynamic range

- Free up space on the GC

- No toxic metals: The Jetanizer™ does not contain nickel catalysts

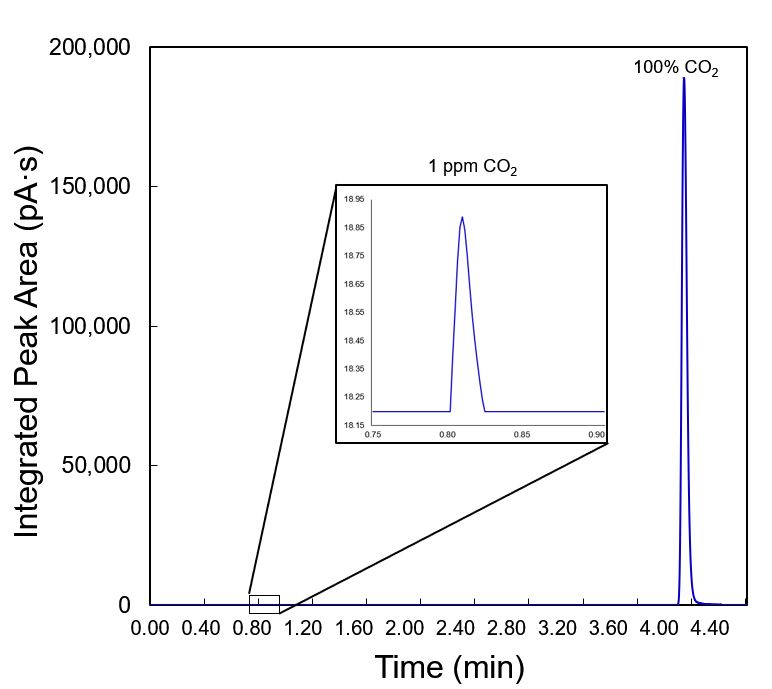

Does the Jetanizer offer simpler analysis of CO and CO2?

The Jetanizer allows you to maintain your chromatography while achieving simpler analysis. This chromatogram shows CO2 conversion to methane from 1 ppm to 100% concentrations.

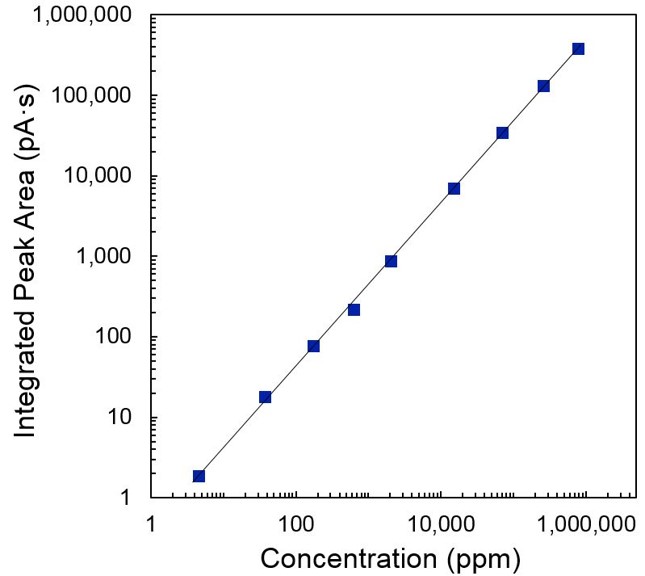

The Jetanizer’s higher catalytic activity, as compared to nickel catalysts, allows for a larger linear dynamic range.

Here, a linear dynamic response to CO2 is depicted, from ppm to 100% concentrations.