Biomass plastics are biodegradable materials that are produced from renewable biomass sources, such as vegetable fats and oils. Many disposable items, such as packaging, plastic bags, and bowls, use biomass plastic materials. Due to their chemical characterization, biomass plastics are being used more often, and manufacturers seek accurate analytical instrumentation to test the composition, quality control, and failure reasons as the products are made in the supply chain.

In this article, we explore how pyrolysis-GC/MS is used to analyze the chemical composition of biomass plastic bags. Two types of commercially available biomass plastic bags are deformulated using a Frontier EGA/PY-3030D micro-furnace pyrolyzer directly interfaced with a GC injector. The micro-furnace pyrolyzer is a multi-functional furnace that can perform Evolved Gas Analysis (EGA), Thermal Desorption (TD), Continuous Flash Pyrolysis (PY), Double-Shot (TD followed by PY), and Heart-Cutting (thermal slicing up to 8 zones).

In this experiment, EGA and TD modes of operations are demonstrated to show the power and simplicity of the Multi-Furnace Pyrolysis-GC/MS technique. Other modes of operation, such as a double-shot or heart-cutting, can also be used to analyze the samples further.

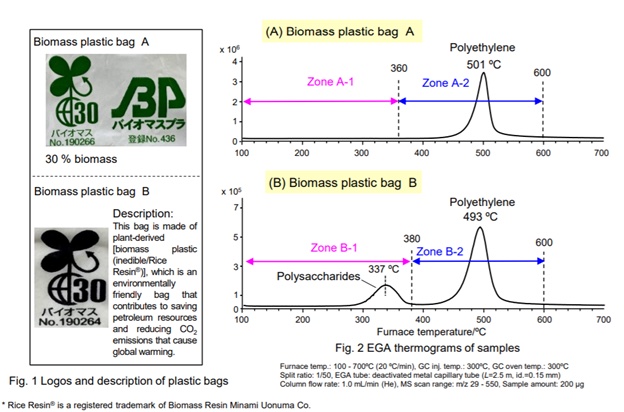

Using the micro-furnace pyrolysis-GC/MS technique, solids can be analyzed without any solvent extraction or pretreatment. The micro-furnace introduces solids into GC/MS system and broadens the range of organic chemical composition analysis. In this experiment, the unprinted part of a plastic bag shown in Figure 1 was cut into small pieces using a cutting knife and was placed in an inert Eco-Cup. The entire analysis is also automated using the Frontier Auto-Shot Sampler.

EGA-MS is the first step in material characterization. To perform EGA, the GC injector and the MS detector are connected through a deactivated metal tube, and the micro-furnace is programmed from 100 to 700 °C while keeping the GC oven isothermal at 300 °C.

The EGA thermograms of Biomass plastic bags A and B are shown in Figure 2. For Biomass plastic bag A, a peak at 501 °C is observed in Zone A-2. For Biomass plastic bag B, a small peak is detected in Zone B-1. Based on the description of plastic bag B, this peak is due to the thermal decomposition of polysaccharides derived from Rice Resin. In Zone B-2, a peak at 493 °C is observed. Two peaks observed at 501 °C (A) and 493 °C (B) are derived from polyethylene by their average mass spectra. The small difference in the peak temperature can be attributed to the differences in the polyethylene used.

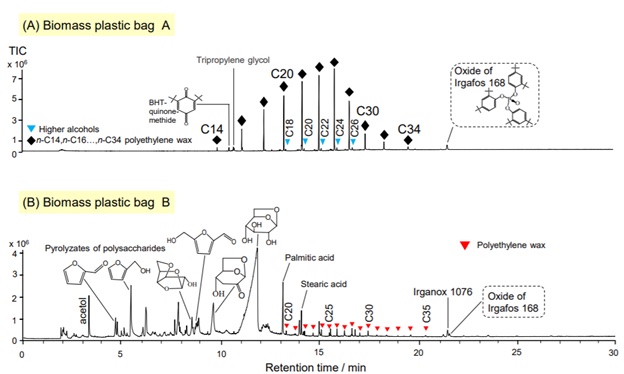

The optimal Thermal Desorption (TD) temperature zones were identified for both plastic bags using the contained EGA thermograms. The volatile components released from the sample were cryo-trapped at the head of a separation column by the Frontier MicroJet Cryo-Trap (VIDEO). They were then analyzed by GC/MS to obtain TD chromatograms upon turning off the MicroJet Cryo-Trap. The standard addition method was used for the quantification of volatile antioxidants.

The TD chromatograms of Biomass plastic bags are shown in Figure 3. Both samples were found to contain a variety of additives. The concentrations of antioxidant Irgafos 168 in Biomass plastic bags A and B were determined to be 450 ppm and 95 ppm, respectively. Several pyrolyzates derived from polysaccharides are observed in Fig 3 (B) and are considered deriving from the Rice Resin [Frontier Laboratories, Ltd.].

Fig. 3 TD chromatograms of Biomass plastic bag A and Biomass plastic bag B Furnace temp.: Biomass plastic bag A 100 – 360 ⁰C (40 °C/min); Biomass plastic bag B 100 – 380 ⁰C (40 °C/min) GC inj. temp.: 300°C, GC oven temp.: 40 (2 min hold) – 320ºC (20 °C/min), Split ratio: 1/10 Separation column: UA+ -5 (5 % diphenyl 95 % dimethylpolysiloxane), L=30 m, i.d.=0.25 mm [Frontier Laboratories, Ltd.]

To analyze the polymeric and heavier fraction of the samples, continuous flash pyrolysis (Single-Shot) mode of operation can be used. In addition, the Double-shot mode of operation enables two analyses on each sample: TD followed by flash pyrolysis.

This technical note was developed by Frontier Laboratories Ltd. 4-16-20 Saikon, Koriyama, Fukushima, 963-8862 JAPAN. www.frontier-lab.com

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions