The polymer industry is involved in just about every industry there is – including the world of fashion. And for textile manufacturers, high margins, rapid production, and synthetic dupes for every organic textile are always in vogue. Competing in this industry are traditionalist manufacturing sectors, like leather goods makers who, despite their arduous process of qualifying leather, are meeting plastic competition at every corner. As a result, characterizing synthetic and organic textiles is an application of growing importance.

There is strong consumer demand in both the synthetic and organic textiles markets. Some consumers seek out fake or plastic leather (pleather) intentionally. However, there are also consumers who erroneously believe what they are purchasing is “real” leather. Their purchase often mimics the real-thing so accurately, it is almost undetectable. And only later do they find out that their designer bag or leather couch is made of synthetic materials.

Thus, I set out to local thrift shop and sampled a motley crew of textiles with leather finishes to see if one can find genuine hide second-hand. And I was one step closer to completing my mission to characterize synthetic and organic textiles.

To assist with the experiment, a Frontier EGA/PY-3030D multi-mode pyrolyzer integrated with an Agilent 7890B with 5977A GC/MSD system were employed. For a simple technique to differentiate the materials of concern, flash pyrolysis was chosen in tandem with GC/MS. In flash pyrolysis, a sample placed in a micro-furnace is applied a quick, single temperature hold, often at high heat. This thermal application breaks bonds but keeps polymer chains and other components intact. Thus, it produces small enough molecules to be analyzed by GC. [To learn more about Flash Pyrolysis, check out this great video from Frontier Labs.]

The result is a nice overview of the sample’s constituents, with pyrolyzates from polymers and additives in one chromatogram. The pyrolysis temperature is determined by evolved gas analysis (EGA), the sample’s thermal profile obtained by the same microfurnace, but with ramped heat and pyrolyzates flowing directly to the MS.

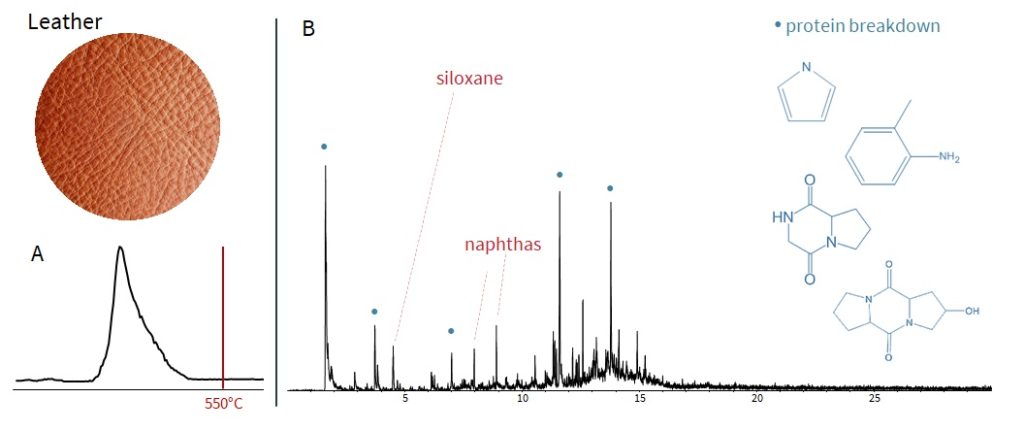

A swatch of crafting leather served as the leather reference. It turned out that much of the pyrolyzates of animal hide are attributed to protein breakdown. Interestingly, this crafting leather contained siloxane and petroleum distillates (naphthas) foreign to biomatter. The source is likely ingredients from a silicone spray or grease added to waterproof the surface. Post-discovery, I did splash water on the craft leather, and it did pool water.

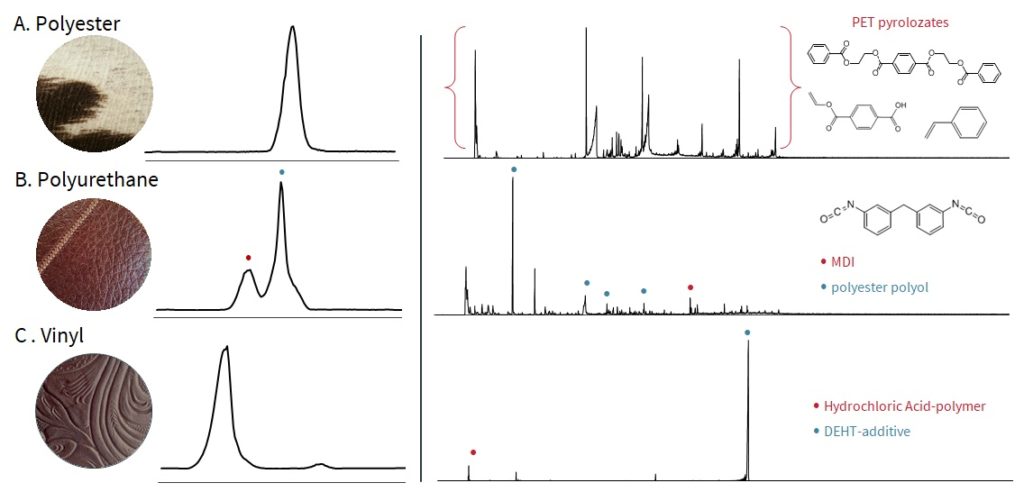

The three main varieties of pleather are vinyl, polyester, and polyurethane. Plasticized vinyl and polyurethane have the sturdiness and flexibility to suffice in applications where leather is used. In pleather, vinyl and polyurethane are usually layered on a base of polyester or organic fibers. Polyester is a softer polymer, which cannot mimic top grain by itself. But it can be made to look like soft hair. To test these polymers in a pyrolysis application, I gathered furniture upholstery of each variety as references.

Those in the textiles and polymer industries understand the complexity of polymers due to the limitless combinations of monomers, comonomers and additives associated with each kind. With targeted chromatography and polymer libraries, the specific type of polyester (polyethylene terephthalate), the two moieties of polyurethane (MDI and polyester based polyol) and the plasticizer in vinyl were identified. These finer details are often lost in using other methods.

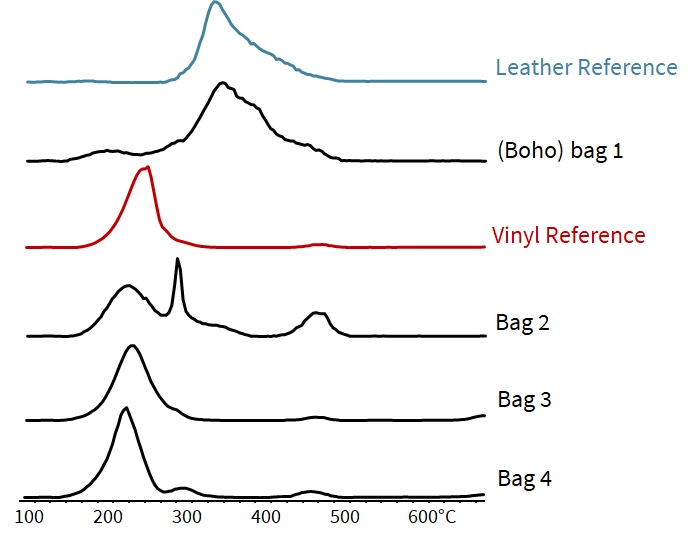

With confidence in instrumentation, it was time to sample the second-hand bags. Through matching mass spectral data and thermal profiles from the EGA analysis alone, three bags were already ruled out as vinyl pleather. One boho-style bag however, showed promise.

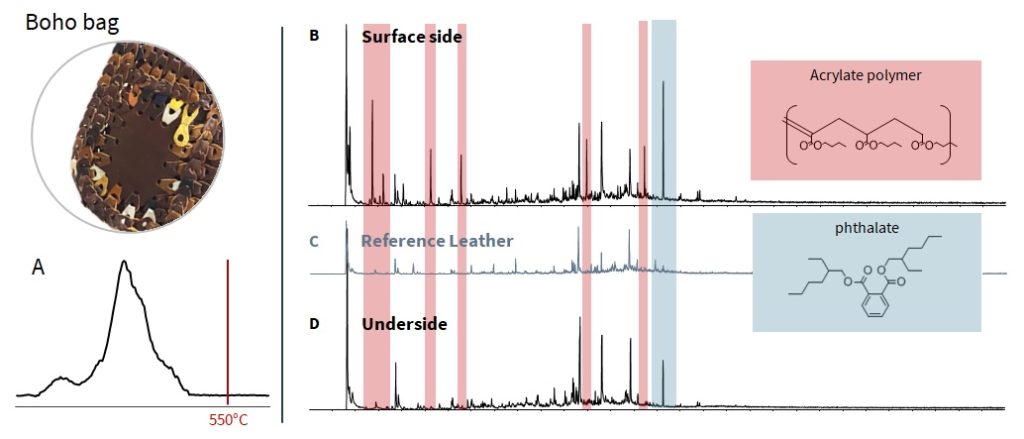

However, flash pyrolysis revealed that the boho-bag oddly contained acrylate polymer and phthalate along with protein pyrolyzates. The addition of plastic would suggest bicast or bonded leather. These are “cheaper” leathers made by adding polymer in some way to scrap or lower grain hide. A suspicion led me to test the surface and underside separately.

After confirming the lack of acrylic on the underside of the leather and with knowledge that plasticizers are used in acrylic paints, it is likely this leather bag was painted. Perhaps the paint was used to disguise a significant differentiation in color amongst the weaves but on the same leather base?

Yes! So for those who seek real genuine leather from a thrift store, let this be a story that offers hope in your quest. The ubiquity of plastic is clear, even in the commercial leather industry. Therefore, just as other traditional polymer industries like paints, coatings, and fillers, we find another interesting use-case for pyrolysis-based analyzers.

Complete this form below to sign up and we will reach out to you with instructions