What happens if you are tasked with identifying an unknown sample? Say hello the the Method Map!

Today, analytical pyrolysis encompasses much more than simple flash pyrolysis of polymeric materials. Virtually any solid or liquid material can be characterized using an array of techniques, which are designed into a modern day, multi-functional pyrolysis system. Let’s explore the 2-step method map for identifying unknown samples using the Frontier Multi-Shot Pyrolyzer.

Step 1

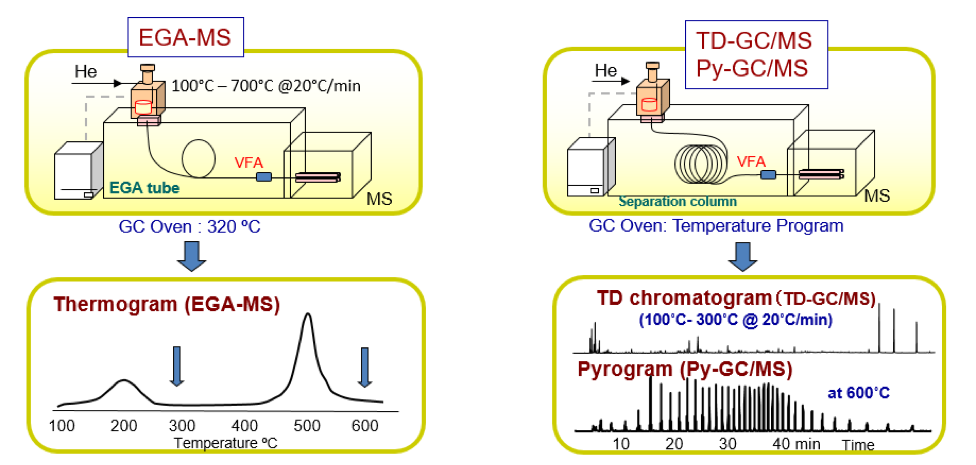

The first step in analyzing the unknown sample is Evolved Gas Analysis (EGA) technique. EGA provides a “picture” of the sample’s complexity. In this technique, the sample is dropped into the furnace which is at a relatively low temperature. The furnace is then programmed to reach a much higher temperature. Compounds “evolve” from the sample as the temperature increases and then a plot of detector response vs. furnace temperature is obtained.

Step 2

The second step of the method map is to analyze the thermal zones of interest obtained from EGA thermogram. In this step, a Frontier Selective Sampler slices a thermal zone out of the sample and separates the components chromatographically using a Mass Spectrometer (MS). This technique is called Heart Cutting (HC) and provides up to 8 programmable temperature zones for analyzing the unknown sample. Volatile compounds can be reliably chromatographed using a Frontier MicroJet Cyro-trap that Cyro-focus the components at the head of the analytical column prior to starting the chromatographic run. Or a Thermal desorption chromatogram (referred to as TD-GC/MS) can be obtained by a customized temperature programming of the micro-furnace of pyrolyzer. After TD-GC/MS, the sample can be subjected to a pyrolysis temperature. The obtained pyrogram is then referred to as PY-GC/MS.

The figure above illustrates EGA-MS and TD/PY-GC/MS configurations. In this example, a Double-Shot method using the obtained EGA thermogram from the Frontier Multi-Shot Pyrolyzer is developed. One can learn about the volatiles and/or additives in the sample by simply programming the Frontier Pyrolyzer furnace temperature from 100 to 300 °C. This stage of analysis identifies only the compounds between the set temperature range (100 – 300 °C) by transporting the evolved compounds to the head of the analytical column. To study the second peak in EGA, the furnace temperature can be set to 600 °C to obtain a pyrogram for any polymeric and/or heavier compounds identification.

EGA uses a Frontier uncoated and inert stainless-steel tube (2.5m x 0.15mm i.d.) to connect the GC inlet to MS. Subsequence analyses (TD-GC/MS and PY-GC/MS referred to as Double-Shot) are performed using a Frontier analytical column (30m x 0.25mm x 0.25µm). Switching from the metal tube to the analytical column takes only minutes using Frontier Vent-free GCMS Adaptor (VFA).

Summary

Frontier Multi-Shot Pyrolyzer is an extremely efficient technique in identifying an unknown composition with two simple steps. Among its many advantages, the Frontier Multi-Shot Pyrolyzer provides a clear picture of the unknowns’ composition by identifying the thermal zones and the compounds in each zone. The instrument allows multiple analysis on a single sample, and there is no need for solvent and sample preparation. By leveraging the power of the Method Map and the Frontier EGA/PY-3030D pyrolysis system, you can expand the boundaries of your material characterization.

References:

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions