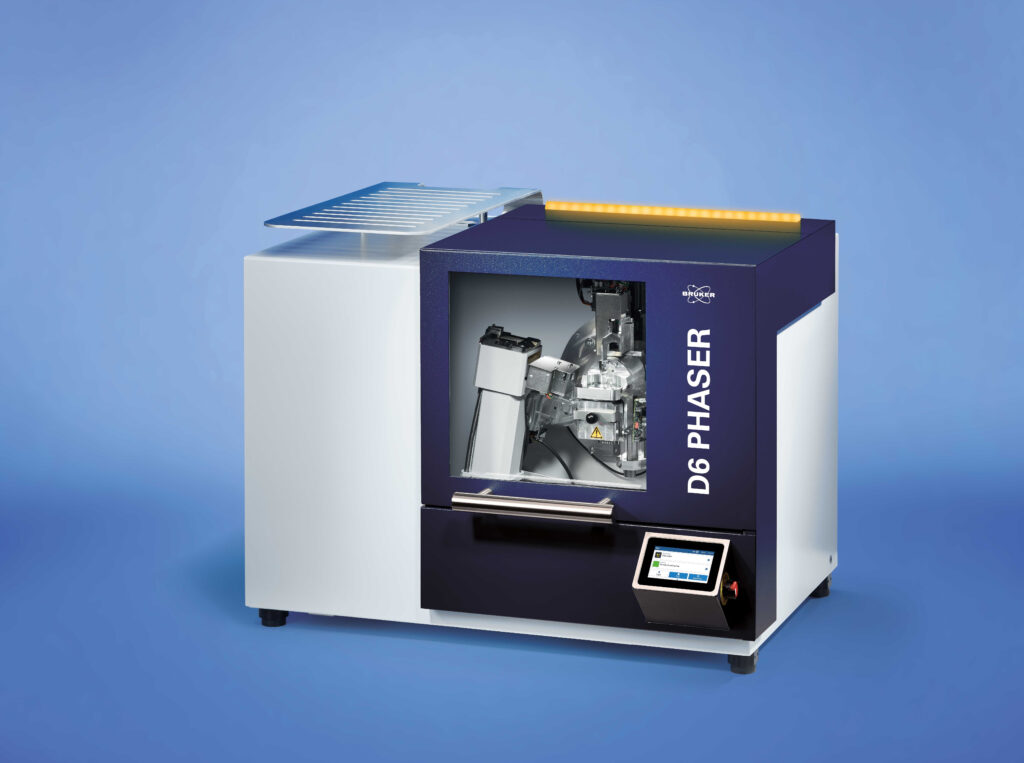

The D6 PHASER XRD is Bruker’s new XRD platform. It’s compact benchtop design delivers the analytical flexibility typically only available in larger, floor-standing systems. Unlike conventional, more limited benchtop XRD instruments, the D6 PHASER enables analytical methods that go beyond powder diffraction. With its wide range of capabilities, the D6 PHASER will enable more XRD applications for new markets and user communities.

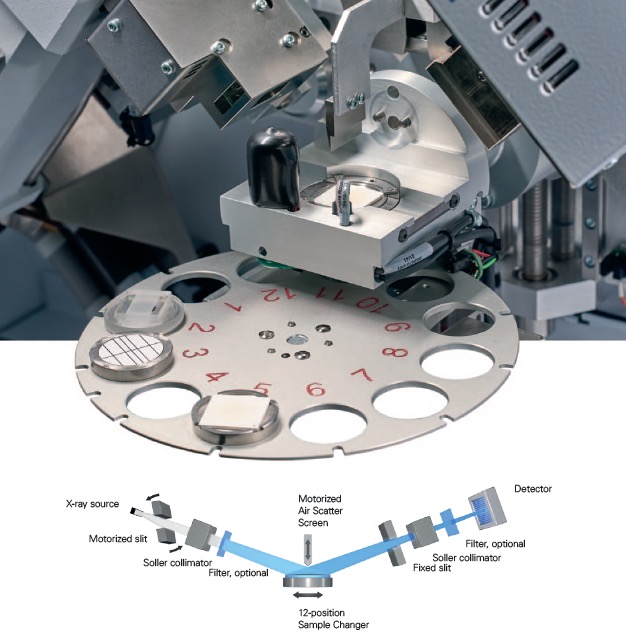

Building on the success of the previous model, the D2 PHASER, the D6 PHASER combines the functionality of the floor-standing D8 platform with an innovative benchtop design that includes high X-ray excitation power and a versatile set of X-ray optics. The Motorized Air Scatter Screen (MASS) enables Dynamic Beam Optimization (DBO) for optimum performance over the goniometer range.

With the automated optimization using DBO and the high signal of the D6 PHASER, measurements become amazingly fast. The optional 12-position Sample Changer allows users to load it up and walk away. Each position can be programmed with a different method and filled with a different sample holder from our extensive catalogue.

The D6 PHASER can be equipped with a range of sample stages for a large variety of X-ray diffraction applications, including capillary transmission, grazing incidence diffraction, X-ray reflectometry, residual stress, texture analysis, and non-ambient investigations. The DaVinci stage-interface allows swapping sample stages without realignment.

The patented D6 PHASER goniometer provides intrinsic angular accuracy of ≤0.01° over the 2θ range. With a touch on the integrated panel, the D6 PHASER automatically performs verification of angular accuracy.

The D6 PHASER XRD offers the family of LYNXEYE™ detectors. For the analysis of non-perfect powder samples, the user can select the patented Bragg2D™ method. The optional LYNXEYE XE-T detector offers proprietary suppression of Cu-Kß reflections, without the usual constraints when using a Kß metal filter.

The versatile D6 PHASER XRD combined with DIFFRAC.SUITE™ software provides flexibility for automated push-button methods or to customize measurement configurations for optimized data quality. The D6 PHASER needs no external water cooling and has no special electrical requirements for convenience to bring versatile, high-performance XRD to any laboratory. Finally, the D6 PHASER complies with the latest radiation protection and machinery directives, and it is available as a GxP compliant solution.

One application that demonstrates the capabilities of the D6 PHASER is crystallite size analysis. Crystallite size analysis is an important application in the chemical and pharmaceutical industries. This is because process parameters or material properties are closely related to crystallite size or surface area. Read why the D6 PHASER XRD is ideally suited for rapid crystallite size analysis using powder X-ray diffraction.

There are a ton of amazing features and capabilities designed into the new D6 PHASER benchtop XRD. Read about them in the D6 PHASER product brochure.

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions