There are a few different options when it comes to carrier gases used in gas chromatography – nitrogen, helium, and hydrogen.

In recent years, managing helium supply has been a challenge for labs. Despite being the second most abundant element in the universe, helium’s availability on Earth is low. It is formed from the radioactive decay of uranium and thorium in granite rocks in the Earth’s continental crust.

Most helium atoms produced this way diffuse to the Earth’s surface, into the atmosphere and then into space and, currently, there is no economical way to capture the atoms directly. In fact, 97% of the helium captured for use is obtained as a by-product of the extraction of natural gas from the ground, but the number of gas fields in the world with enough helium to justify the cost of the separation process to obtain it (a helium content of at least 0.3%) is decreasing.¹ Also, after it has been used, helium is not re-captured for re-use.

With this issue growing as a concern for lab managers, what can be done about it?

Leading analytical instrumentation manufacturers are addressing the complication surrounding helium and are offering solutions for moving to hydrogen as a carrier gas for gas chromatography.

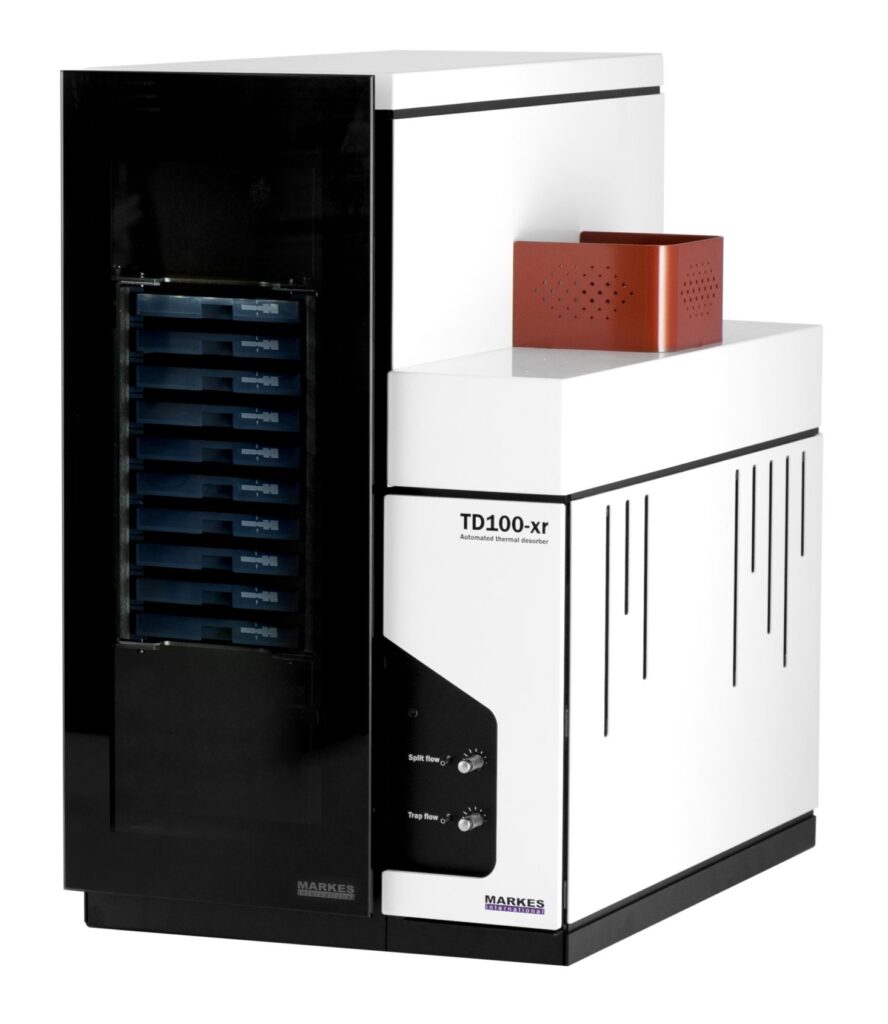

To combat these issues, TD (Thermal Desorption) instruments manufacturers Markes International have turned towards making their range of TD systems multi-gas enabled. In short, this feature allows them to switch between the three gases – helium, nitrogen, and hydrogen.

Not only is this convenient for analysts during helium shortages, using hydrogen means it is also better for the environment. Helium needs to be extracted, shipped, and stored using specialized equipment.

Hydrogen, on the other hand, is simple to generate using just water and electricity. Switching from helium to hydrogen saves up to 90% per cylinder.

Further, purchasing an in-house hydrogen generator eliminates the need for cylinder deliveries, significantly reducing a laboratory’s costs and carbon footprint.

Learn more about moving to hydrogen as a carrier gas for thermal desorption GC/MS analysis with our on-demand webinar.

References:

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions